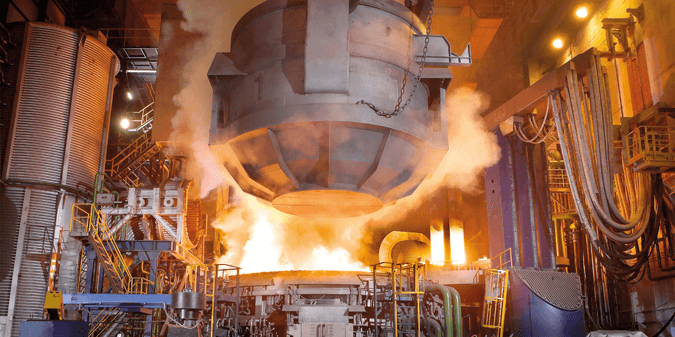

EAF Dust

EAFD is a hazardous solid waste and environmental pollutant which is generated in the collection of particulate material during steelmaking process via electric arc furnace. It is a fine powder passed through cooling pipes and then filled and kept in specially designed bag filters. The world generation of EAFD is estimated to be around 3.7 million tons per year. Such significant quantity is due to the fact that for every ton of recycled steel an amount of 15-20 kg of EAFD is produced. It had been a problem for many years as it acquires a fair deal of money to be taken care of and to save the environment from its polluting effects. The cost of EAFD disposal is not negligible. For example, 200 million dollars per year are necessary to dispose EAFD in the United States.

Current Praxis

EAFDust also contains Pb, Cd, Cr and Ni in oxide forms and halides, with NaCl and KCl in small amounts. Currently, the processes for treating EAFD from steel making can be classified into either pyrometallurgical or hydrometallurgical processes that produce either zinc oxide or metallic zinc. For the pyrometallurgical treatment, high temperatures are involved and the recovery rate of zinc is low. Despite numerous technologies available for the pyrometallurgical treatment of EAFD most are still based on carbothermic (carbon) processes that produce carbon dioxide and carbon monoxide which pass to the environment.

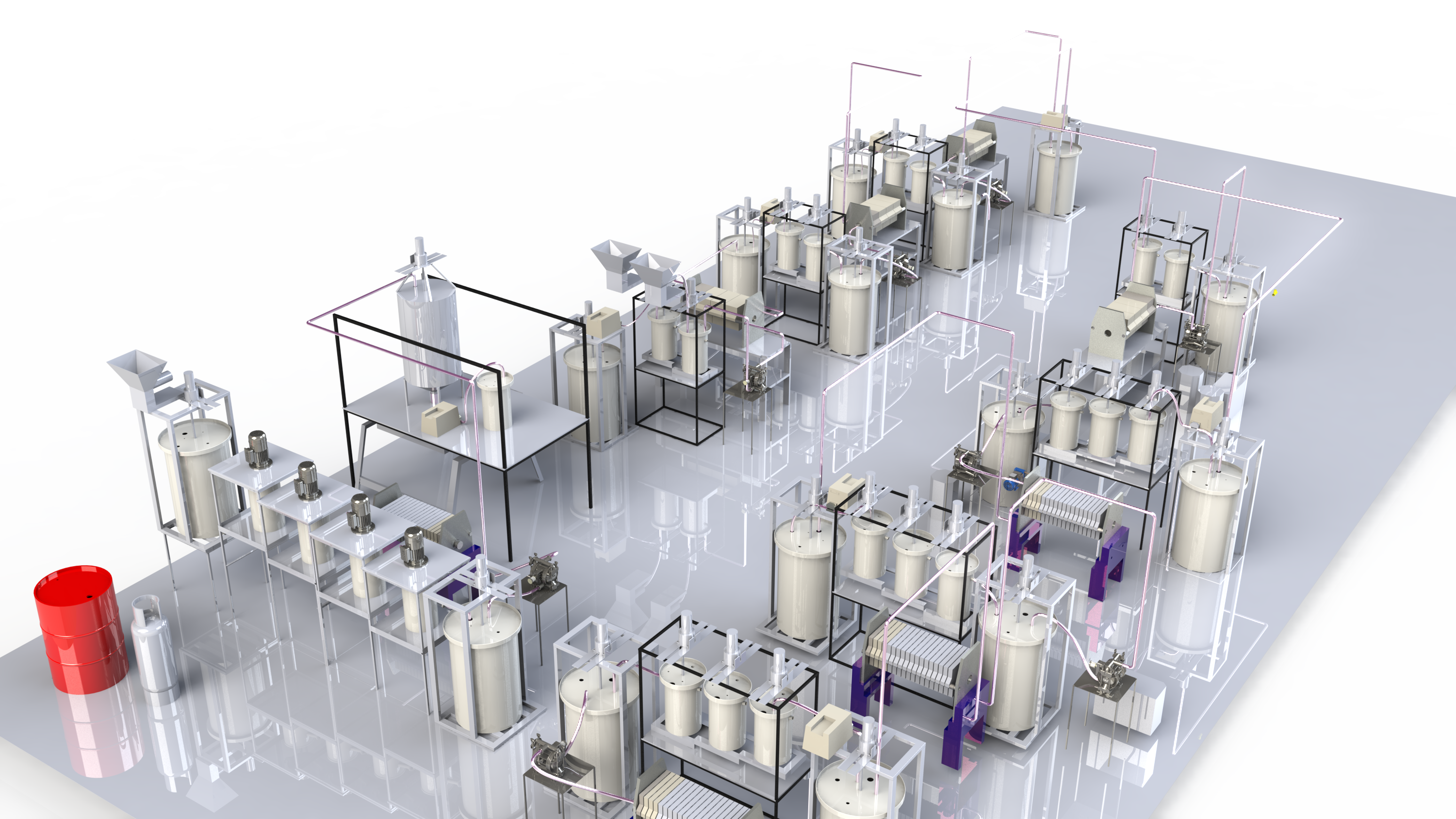

ZnCor Process

Numerous pyrometallurgical and hydrometallurgical processes have been attempted, but the problem with such processes has been their inability to generate a pure product suitable either for market or for return to the steel plant.

The ZnCor Process fully recovers ultra hi purity zinc oxide and associated value metals, such as lead, silver, copper, manganese, iron and cadmium in a marketable form from various zinc-bearing feedstocks, including Spent zinc pickle liquor (ZPL). ZPL is the waste product containing zinc and ferrous chlorides from steel plant galvanizing pickling lines. At the present time, there is no method for treating this, and it is commonly disposed of by deep well injection.

ZnCor Consortium

ZnCor Consortium is an integrated metals production and technology alliance specialized in the sustainable processing of Electric Arc Furnace Dust (EAFD) and Spent Pickle Liquor (ZPL). The Consortium is positioned to become the world’s premier zinc refiner with exclusive, fundamental competitive advantages that will enable it to consolidate key industrial recycling initiatives.

Contact us

DISCLAIMER

Your communication

is private and confidential.

ZnCor does not share nor sell

any confidential information to third parties.

Phone :

Email :

Address :

All rights reserved - Copyright © ZNCOR 2021